Roti Production Line Machine CPE-650

Roti Production Line Machine CPE-650

| Size | (L)22,610mm * (W)1,580mm * (H)2,280mm |

| Electricity | 3 Phase ,380V,50Hz,53kW |

| Capacity | 3,600(pcs/hr) |

| Model No. | CPE-650 |

| Press size | 65*65 cm |

| Oven | Three level |

| Cooling | 9 level |

| Counter Stacker | 2 row or 3 row |

| Application | Tortilla, Roti, Chapati, Lavash, Burrito |

Roti (also known as chapati) is a round flatbread native to the Indian subcontinent made from stoneground whole wheat flour, traditionally known as gehu ka atta, and water that is combined into a dough. Roti is consumed in many countries worldwide. Its defining characteristic is that it is unleavened. Naan from the Indian subcontinent, by contrast, is a yeast-leavened bread, as is kulcha. Like breads around the world, roti is a staple accompaniment to other foods. Most roti are now manufactured by hot press. The development of Flatbread hot press is one of the core expertise’s of ChenPin. Hot-press roti are smoother in surface texture and more rollable than other roti.

For More details picture please click on detailed photos.

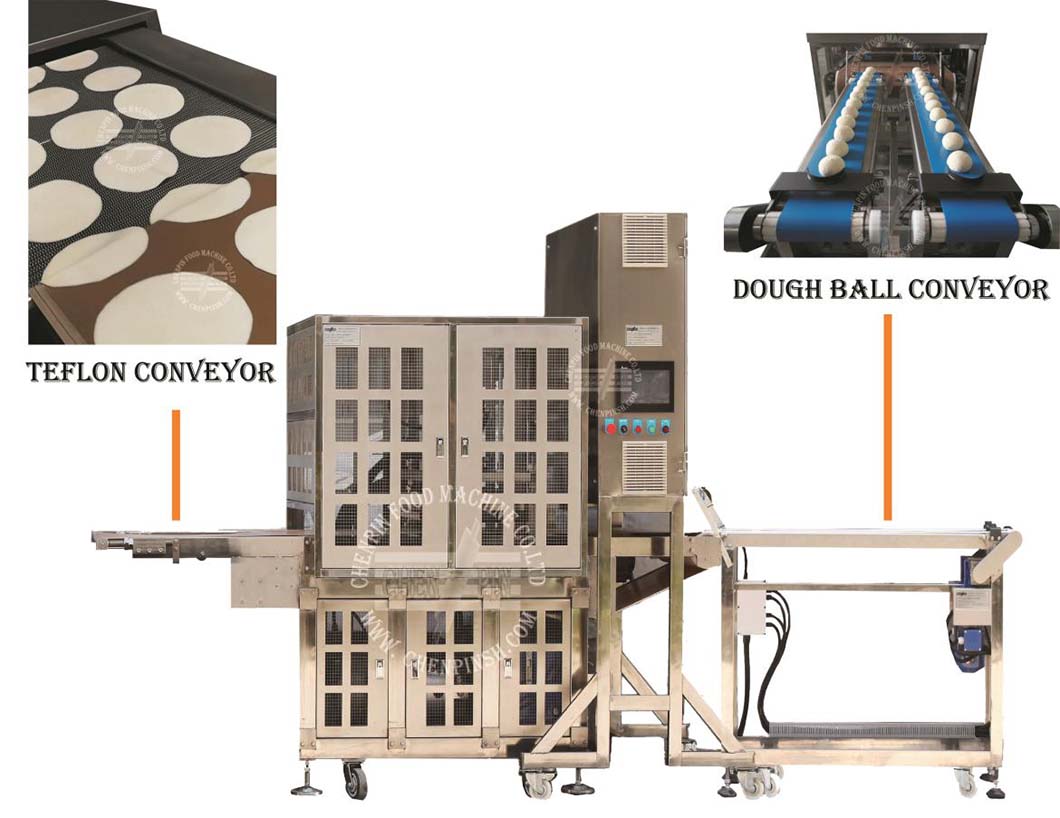

1. Roti Hydraulic hot press

■ Safety interlock: Presses dough balls evenly without being affected by the hardness and shape of dough balls.

■ High-productivity pressing & heating system: Presses 4 pieces of 8-10 inch products at a time and 9 pieces of 6 inch The average production capacity is 1 piece per second. It can run at 15 cycles per minutes and press size is 620*620mm

■ Dough ball conveyor: Distance between dough balls is automatically controlled by sensors and 2 row or 3 row conveyors.

■ Superior control of product positioning during pressing to increase product consistency while minimizing waste.

■ Independent temperature controls for both top and bottom hot plates

■ Hot press technology give enhance the rollability property of roti.

Photo of Roti Hydraulic hot press

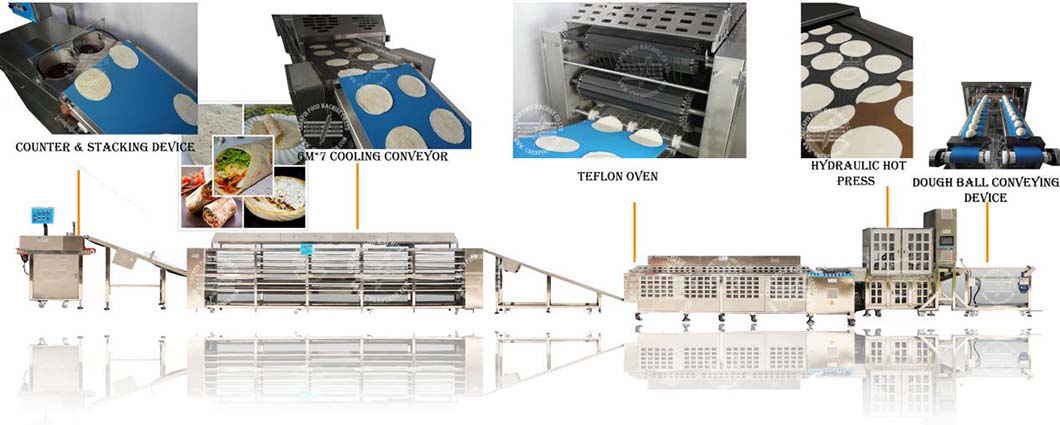

2. Three layer/level tunnel oven

■ Independent control of burners and top/bottom baking temperature. After turning on, the burners are automatically controlled by temperature sensors to ensure constant temperature.

■ Flame failure alarm: Flame failure can be detected.

■ Size: 4.9 meter long oven and 3 level which will enhance roti bake on both side.

■ Provide maximum efficiency and uniformity in baking.

■ Independent temperature controls. 18 Igniter and ignition bar.

■ Independent burner flame adjust and gas volume

■ Automatic temperature adjustable after feeding the temperature required.

Photo of Three Level Tunnel Oven for Roti

3. Cooling system

■ Size: 6 meter long and 9 level

■ Number of cooling fans: 22 Fans

■ Stainless steel 304 mesh conveyor belt

■ Multiple tier cooling system for reducing baked product temperature prior to packaging.

■ Equipped with variable speed control,independent drives, alignment guides and air management.

Cooling conveyor for Roti

4. Counter Stacker

■ Accumulate stacks of roti and move the roti in a single file to feed packaging.

■ Able to read the pieces of the product.

■ Equipped with the pneumatic system and hopper are used to control the motion of the product to accumulates it while stacking.

Photo of Counter Stacker machine for Roti

Automatic Roti Production line machine working process

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)