Chapati Production Line Machine CPE-650

Chapati Production Line Machine CPE-650

| Size | (L)22,610mm * (W)1,580mm * (H)2,280mm |

| Electricity | 3 Phase ,380V,50Hz,53kW |

| Capacity | 3,600(pcs/hr) |

| Model No. | CPE-650 |

| Press size | 65*65 cm |

| Oven | Three level |

| Cooling | 9 level |

| Counter Stacker | 2 row or 3 row |

| Application | Tortilla, Roti, Chapati, Lavash, Burrito |

Chapati (alternatively spelled chapatti, chappati, chapathi, or chappathi, also known as roti, rotli, safati, shabaati, phulka and (in the Maldives) roshi, is an unleavened flatbread originating from the Indian subcontinent and staple in India, Nepal, Bangladesh, Pakistan, Sri Lanka, East Africa, Arabian Peninsula and the Caribbean.Chapatis are made of whole-wheat flour known as atta, mixed into dough with water, oil and optional salt in a mixing utensil called a parat, and are cooked on a tava (flat skillet).

It is a common staple in the Indian subcontinent as well as amongst expatriates from the Indian subcontinent throughout the world.

Most chapati are now manufactured by hot press. The development of Flatbread hot press is one of the core expertise’s of ChenPin. Hot-press roti are smoother in surface texture and more rollable than other chapati.

For More details picture please click on detailed photos

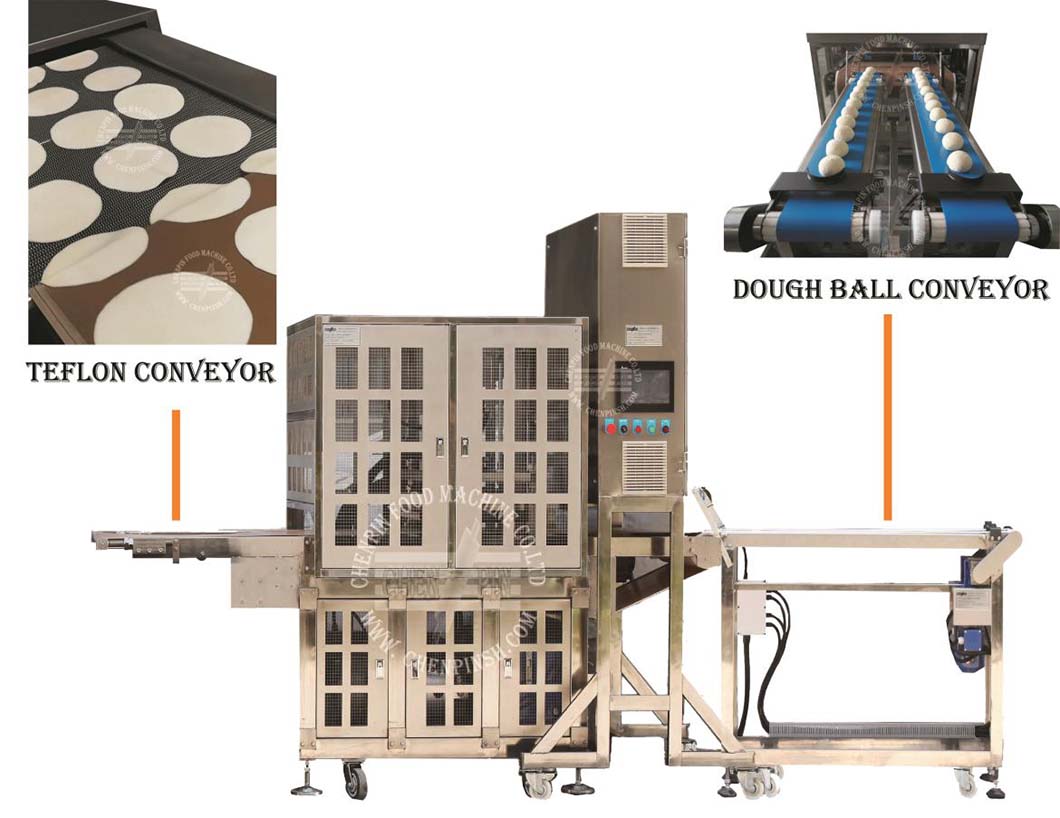

1. Chapati Hydraulic hot press

■ Safety interlock: Presses dough balls evenly without being affected by the hardness and shape of dough balls.

■ High-productivity pressing & heating system: Presses 4 pieces of 8-10 inch products at a time and 9 pieces of 6 inch The average production capacity is 1 piece per second. It can run at 15 cycles per minutes and press size is 620*620mm

■ Dough ball conveyor: Distance between dough balls is automatically controlled by sensors and 2 row or 3 row conveyors.

■ Superior control of product positioning during pressing to increase product consistency while minimizing waste.

■ Independent temperature controls for both top and bottom hot plates

■ Hot press technology give enhance the rollability property of chapati.

Photo of Chapati Hydraulic hot press

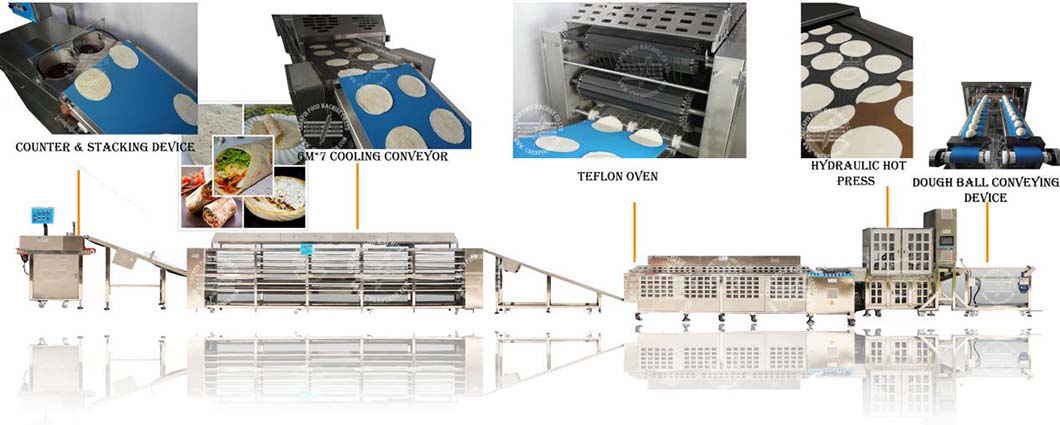

2. Three layer/level tunnel oven

■ Independent control of burners and top/bottom baking temperature. After turning on, the burners are automatically controlled by temperature sensors to ensure constant temperature.

■ Flame failure alarm: Flame failure can be detected.

■ Size: 4.9 meter long oven and 3 level which will enhance chapati bake on both side.

■ Provide maximum efficiency and uniformity in baking.

■ Independent temperature controls. 18 Igniter and ignition bar.

■ Independent burner flame adjust and gas volume

■ Automatic temperature adjustable after feeding the temperature required.

Photo of Three Level Tunnel Oven for Chapati

3. Cooling system

■ Size: 6 meter long and 9 level

■ Number of cooling fans: 22 Fans

■ Stainless steel 304 mesh conveyor belt

■ Multiple tier cooling system for reducing baked product temperature prior to packaging.

■ Equipped with variable speed control,independent drives, alignment guides and air management.

Cooling conveyor for Chapati

4. Counter Stacker

■ Accumulate stacks of chapati and move the chapati in a single file to feed packaging.

■ Able to read the pieces of the product.

■ Equipped with the pneumatic system and hopper are used to control the motion of the product to accumulates it while stacking.

Photo of Counter Stacker machine for Chapati

Automatic Chapati Production line machine working process

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)