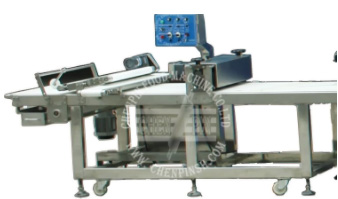

Automatic Pizza Production Line Machine

1. Dough Conveying Conveyor

■After mixing of dough it is rest for 20-30 min. And after fermentation it is then place on Dough conveying Device. From this device it is then transfer to dough rollers.

■Automatic aligning before transfer to per sheeter.

2. Pre Sheeter & Continuous sheeting rollers

■ Sheet is now process in these sheet rollers. These roller inhances dough gluten extensively spread and mix.

■ Sheeting technology is preferred above the traditional system because sheeting provides important benefits. Sheeting makes it possible to handle a wide variety of dough types, from ‘green’ to pre-fermented dough, all at high capacities

■ By using stress-free dough sheeters and laminating technology, you can achieve basically any dough and bread structure desired

■ Continuous sheeter: the first reduction of the dough sheet’s thickness is done by a continuous sheeter. Due to our unique non sticking rollers, we are able to process dough types with high water percentage.

3. Pizza Cutting and Docking Disc Forming

■ Cross roller: to compensate the one-sided reduction of the reduction stations and to adjust the dough sheet in thickness. The dough sheet will reduce in thickness and increase in width.

■ Reduction station: the thickness of the dough sheet is reduced while passing through the rollers.

■ Product cutting and docking(Disc forming): products are cut out of the dough sheet. Docking ensures that the products develop their typical surface and makes sure that there is no bubbling on the product surface during baking. Wastage are returned through conveyor to collector.

■ After cutting and docking it is then transfer to automatic tray arranging machine.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)