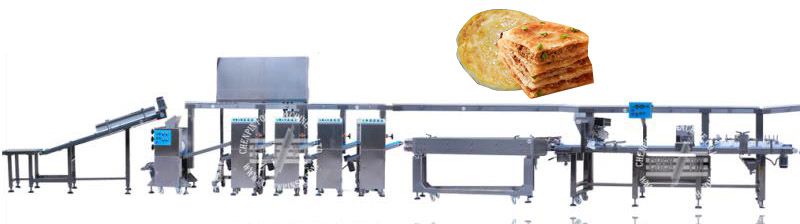

Automatic Lacha Paratha Production Line – Lachha Paratha Production Line Machine CPE-3268 – Chenpin

Automatic Lacha Paratha Production Line – Lachha Paratha Production Line Machine CPE-3268 – Chenpin Detail:

CPE-3268 Automatic Lacha Paratha Dough Ball Production Line

| Size | (L)25,160mm * (W)1,120mm * (H)2,240mm |

| Electricity | 3 Phase,380V,50Hz,17kW |

| Application | Lacha Paratha ,Spring Onion Pie, Thin Dough Products |

| Capacity | 2,100-6,300(pcs/hrs) |

| Production weight | 50-200(g/pc) |

| Model No. | CPE-3268 |

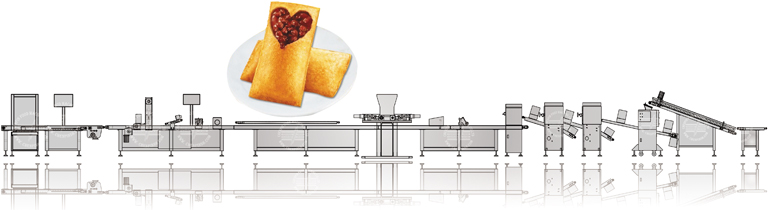

CPE-788B Paratha Dough Ball Pressing and Filming Machine

| Size | (L)3,950mm * (L)920mm * (H)1,360mm |

| Electricity | Single Phase,220V,50Hz,0.4kW |

| Application | Paratha pastry film covering (Packing) and pressing |

| Capacity | 1,500-3,200(pcs/hr) |

| Product Weight | 50-200(g/pcs) |

Lacha Paratha

Sesame cake

Paratha

Baked cake

Product detail pictures:

Related Product Guide:

To get the stage of realizing dreams of our employees! To build a happier, more united and much more skilled crew! To reach a mutual benefit of our prospects, suppliers, the society and ourselves for Automatic Lacha Paratha Production Line – Lachha Paratha Production Line Machine CPE-3268 – Chenpin , The product will supply to all over the world, such as: Iraq, Congo, Palestine, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

1. Filling/Wrapping for puff pastry

■ Automatic Margarine extrusion and wrap it inside dough sheet.

■ Fine thickness are achieve through dough sheeters and side through calibrator. Wastage are collected to hopper.

■ Material of is made of stainless steel 304.

2. Multilevel layering

■ Transverse dough laying units (laminators) with roller spreaders, the development of which allowed to simplify the process of laying the dough ribbon, to provide a wider range of adjustment of the number of layers and more convenient access to the structural elements.

■ This process is repeated twice resulting several layers.

■ As the production line is automatic it is easy to handle and clean.

3. Close View of layers

■ Result of twice layer through Transverse dough laying units result in several layers. You can have a close view of dough produced by ChenPin technology.

■ This line produce dough laminator which can be use to mould into several products like croissant , puff pastry, Egg tart,Layered paratha,etc and may more dough related multi level/layer pastries.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)

2-300x105.png)