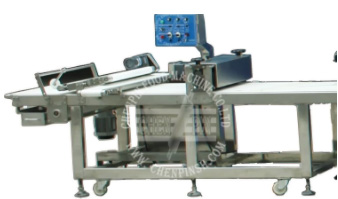

Umshini Wokukhiqiza I-Pizza Ozenzakalelayo

1. I-Conveyor Ehambisa Inhlama

■Ngemva kokuhlanganisa inhlama iyaphumula imizuzu engu-20-30. Futhi ngemva kokuvutshelwa ibekwa kuNhlama ehambisa Idivayisi. Kusukela kule divayisi bese idluliselwa kuma-rollers enhlama.

■Ukuqondanisa okuzenzakalelayo ngaphambi kokudluliselwa kushidi ngalinye.

2. I-Pre Sheeter namarola amashidi aqhubekayo

■ Ishidi manje selicutshungulwa kulawa marola weshidi. Lawa ma-roller athuthukisa inhlama ye-gluten isakazeka kakhulu futhi ixube.

■ Ubuchwepheshe bokwenza amashidi kukhethwa ngaphezu kwesistimu evamile ngoba amaphepha anikeza izinzuzo ezibalulekile. Ukubeka amashidi kwenza kube nokwenzeka ukubamba inhlama ehlukahlukene, kusukela 'kuhlaza' ukuya enhlama ebilisiwe ngaphambili, konke kusezingeni eliphezulu.

■ Ngokusebenzisa amashidi enhlama angenawo ukucindezeleka kanye nobuchwepheshe be-laminating, ungakwazi ukufeza noma iyiphi inhlama nesinkwa osifisayo.

■ Ishidi eliqhubekayo: ukuncishiswa kokuqala kogqinsi lweshidi lenhlama kwenziwa ngeshidi eliqhubekayo. Ngenxa yamarola ethu ahlukile anganamatheli, siyakwazi ukucubungula izinhlobo zenhlama ngamaphesenti aphezulu amanzi.

3. I-Pizza Cutting kanye Nokwakhiwa Kwediski Ye-Docking

■ I-cross roller: ukunxephezela ukuncishiswa kohlangothi olulodwa lweziteshi zokunciphisa kanye nokulungisa ishidi lenhlama ngobukhulu. Ishidi lenhlama lizonciphisa ubukhulu futhi likhuphuke ngobubanzi.

■ Isiteshi sokunciphisa: ubukhulu beshidi lenhlama buncishisiwe ngenkathi kudlula ama-roller.

■ Ukusika nokufakwa komkhiqizo (Ukwenza amadiski): imikhiqizo iyasikwa eshidini lenhlama. I-Docking iqinisekisa ukuthi imikhiqizo ithuthukisa indawo yayo evamile futhi iqinisekisa ukuthi akukho ukugebha endaweni yomkhiqizo ngesikhathi sokubhaka. Imfucuza ibuyiselwa ngomthumeli kumqoqi.

■ Ngemva kokusika nokudokha idluliselwa emshinini wokuhlela wethreyi othomathikhi.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)