I-Automatic Ciabatta/Baguette Bread Production Line

CP-6580 Automatic Ciabatta/Baguette Bread Production Line

Imininingwane yomugqa wokwakhiwa kwebhola le-Paratha.

| Usayizi | (L)16,850mm * (W)1,800mm * (H)1,700mm |

| Ugesi | 3PH,380V, 50Hz, 15kW |

| Isicelo | Ciabatta/Baguette Isinkwa |

| Amandla | 1,800-4, 100(ama-pcs/ihora) |

| Ububanzi bokukhiqiza | 530 mm |

| Imodeli No. | I-CPE-6580 |

1. I-Dough Chunker

Ngemva kokuxuba inhlama nokuqinisekisa ukuthi ibekwa kule hopper ukuze kuhlukaniseke inhlama.

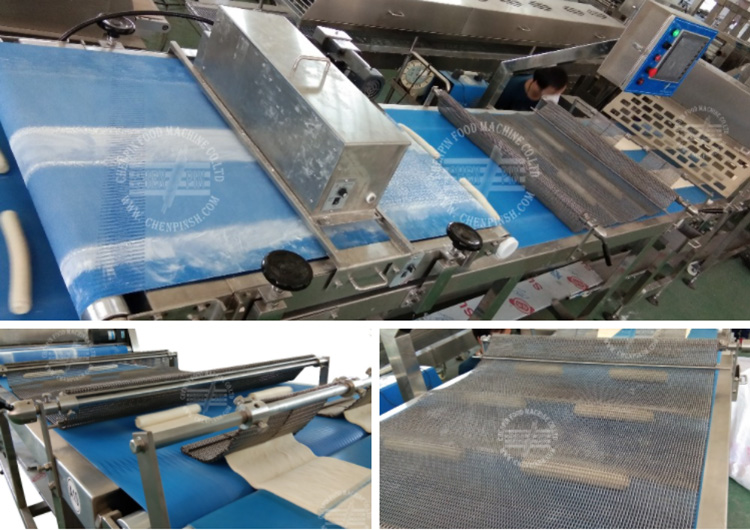

2. I-Pre Sheeting & Continuous sheeting rollers

■ Isivinini seshidi silawulwa kuphaneli yesilawuli. Wonke ulayini ogcwele unekhabhinethi eyodwa ye-elekthronikhi wonke axhumene nomunye nge-PLC ehleliwe futhi ngayinye inephaneli yayo yokulawula ezimele.

■ Ama-pre-sheeters enhlama yesinkwa: yenza amashidi enhlama angagxili anoma yiluphi uhlobo alawula isisindo esisezingeni eliphezulu kakhulu. Isakhiwo senhlama asithintwa ngenxa yokuphatha inhlama ngobungane. Sinezixazululo eziningana ezitholakalayo, kuye ngohlobo lwenhlama.

■ Ukufakwa kwamashidi okuqhubekayo: ukuncishiswa kokuqala kogqinsi lweshidi lenhlama kwenziwa yi-roller eqhubekayo yokwenza amashidi. Ngenxa yamarola ethu ahlukile anganamatheli, siyakwazi ukucubungula izinhlobo zenhlama ngephesenti eliphezulu lamanzi.

■ Isiteshi sokunciphisa: ishidi lenhlama lincishiswa libe ukushuba kokugcina ngenkathi lidlula kumarola.

3. Ukusika nokugoqeka kweshidi lenhlama

■ Ngokubanzi Ukusika ishidi lenhlama emigqeni nokusabalalisa le migqa yenhlama manje sekwenziwa imojuli eyodwa. Iqukethe isisindo esilula, ithuluzi eliyingqayizivele elifanelekile. Iqoqo elilodwa lemimese yokusika lenzelwe ukuvala nokusika inhlama. Ngenxa yesisindo esilula semimese yokusika, ingcindezi ephansi empilweni yebhande lokuthutha isetshenziswa futhi isikhathi sokuphila siyanda. Ukushintsha ngokuhamba kwesikhathi kuncishiswa ngokusebenzisa amathuluzi okusabalalisa ngendlela ehlukile.

■ Itafula lokubumba (Ishidi eligoqiwe) liyadingeka ukuze kukhiqizwe izinhlobo zesinkwa esigoqiwe. Ukusebenza okuvelele kwetafula lokubumba le-ChenPin kusalokhu kungathinteki. Nokho, ukuhlanzeka kalula kanye noshintsho olusheshayo lwenziwa ngokudala ukufinyeleleka okuphelele nhlangothi zombili. Ukusebenza okuphephile kufinyelelwa ukusetshenziswa kokusebenza kwezandla eziphindwe kabili Ngenxa yokuthi u-opharetha oyedwa angahambisa ibhande elingaphezulu ngokushesha nange-ergonomically, ukusebenza kahle kokushintsha kuthuthukisiwe.

■ Imiphetho eyindilinga kanye namakhava avuleke ngokugcwele nhlangothi zombili zeyunithi ngayinye asetshenziswa kulo lonke uhlelo. Ukufinyeleleka okungcono kakhulu nokubonakala kwenqubo kufinyelelwa ngokukhulisa isikhala phakathi kweziteshi zokusebenza. Amathuluzi axhunywe emshinini afakwe ama-standoffs. Ibanga elincane le-intshi elingu-1 lisetshenziswa ukuze kuthuthukiswe imisebenzi yokuhlanza. Ukuphepha sekukonke kuqinisekiswa ukusetshenziswa kwezingidi zokuphepha. Amakhava okuphepha angasindi anezibambo ezengeziwe Isistimu yokugaywa kabusha kwenhlama inika amandla ukusebenza kwe-ergonomic

■ Ngemva kokuyiginqika kunokudlulisela emshinini wokuhlela wethreyi futhi isilungele ukuya engxenyeni elandelayo “lokho okubhaka”

4. Umkhiqizo wokugcina

Isithombe se-baguette ngemuva kokudayela

Isithombe somshini wokukhiqiza isinkwa we-Ciabatta / Baguette

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)