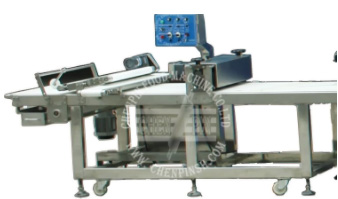

Umatshini woMveliso wePizza ozenzekelayo

1. I-Dough Conveyor Conveyor

■Emva kokuxuba intlama iphumla i-20-30 min. Kwaye emva kokubiliswa ibekwa kwiDough ehambisa iDevice. Ukusuka kwesi sixhobo emva koko idluliselwe kwi-roller inhlama.

■Ulungelelwaniso oluzenzekelayo phambi kokudluliselwa kwiphepha ngalinye.

2. I-Pre Sheeter & Continuous sheeting rollers

■ Iphepha liyalungiswa kwezi rollers zamaphepha. Ezi roller inhances intlama yegluten isasazeke kakhulu kwaye ixube.

■ Itekhnoloji ye-Sheeting ikhethwa ngaphezu kwenkqubo yesiqhelo kuba i-sheeting ibonelela ngeenzuzo ezibalulekileyo. I-Sheeting yenza kube lula ukuphatha iindidi ngeendidi zentlama, ukusuka 'kuhlaza' ukuya kwintlama evundisiweyo, zonke ziphezulu.

■ Ngokusebenzisa amashidi entlama angenaxinzelelo kunye neteknoloji yokulambisa, unokufezekisa ngokusisiseko nayiphi na intlama kunye nesakhiwo sesonka esinqwenelekayo.

■ I-sheeter eqhubekayo: ukucuthwa kokuqala kobunzima bephepha lentlama kwenziwa yi-sheeter eqhubekayo. Ngenxa yeerola zethu ezizodwa ezingancamatheliyo, siyakwazi ukucubungula iintlobo zentlama ngepesenti ephezulu yamanzi.

3. Ukusika iPizza kunye nokwenza iDiskhi yeDocking

■ I-cross-roller: ukuhlawulela ukucuthwa kwelinye icala lezikhululo zokunciphisa kunye nokulungelelanisa iphepha lentlama ngobukhulu. Iphepha lenhlama liya kunciphisa ubukhulu kunye nokwandisa ububanzi.

■ Isikhululo sokunciphisa: ubukhulu bephepha lentlama liyancipha ngelixa lidlula kwii-roller.

■ Ukusika imveliso kunye nokufakwa kwi-docking (ukwenza iDisc): iimveliso zisikwa kwiphepha lentlama. I-Docking iqinisekisa ukuba iimveliso ziphuhlisa umgangatho wazo oqhelekileyo kwaye ziqinisekisa ukuba akukho bhola kwimveliso ngexesha lokubhaka. Inkunkuma ibuyiswa ngomthuthi ukuya kumqokeleli.

■ Emva kokusika kunye nokufakwa kwidokhi emva koko idluliselwe kumatshini wokulungiselela itreyi ezenzekelayo.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)