In the rapidly changing and highly competitive food industry, efficient, intelligent, and customized production solutions have become the key for enterprises to stand out. ChenPin Food Machine Co., Ltd, a leader in the industry, leads a new round of transformation in the field of food machinery with its more than 20 years of profound heritage and professional R&D team. Chenpin not only provides high-quality food molding equipment but also focuses on providing customers with a one-stop overall plant planning service from factory planning to equipment customization, installation and debugging, and even after-sales maintenance, making food production more intelligent and efficient.

One-stop planning: Precise matching, tailor-made.

Chenpin understands the unique needs of every customer, whether it is a new factory construction or an old factory renovation. We can carry out scientific and rational overall plant planning and design based on factors such as factory area budget, equipment capacity requirements, and labor costs. From the layout of the production process to the configuration of equipment, every step strives for the best solution to ensure the maximization of resources and a significant increase in production efficiency.

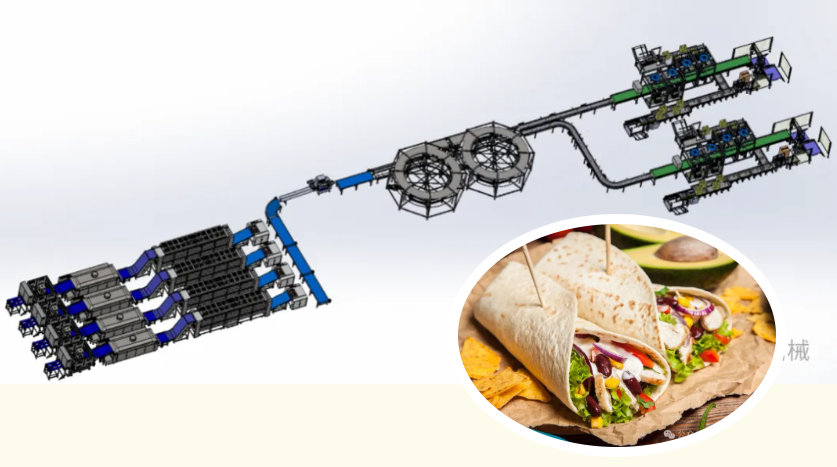

Tortilla Production Line: A Classic Hit Sold Globally

Among the many product lines, Chenpin's one-stop planning for the tortilla production line is particularly eye-catching. This production line integrates automation and intelligence, not only producing tortillas that meet the tastes of different countries efficiently and stably but also meeting the market's demand for high-quality food in terms of taste and size. Chenpin's one-stop planning, customized for companies such as successfully achieved a high capacity of 16,000 pieces per hour. In addition, the flexibility of the production line is not only reflected in the adjustment of capacity but also in the customization of the formula. This allows customers from different countries to adjust the production line configuration according to their market demand, achieving differentiated competition.

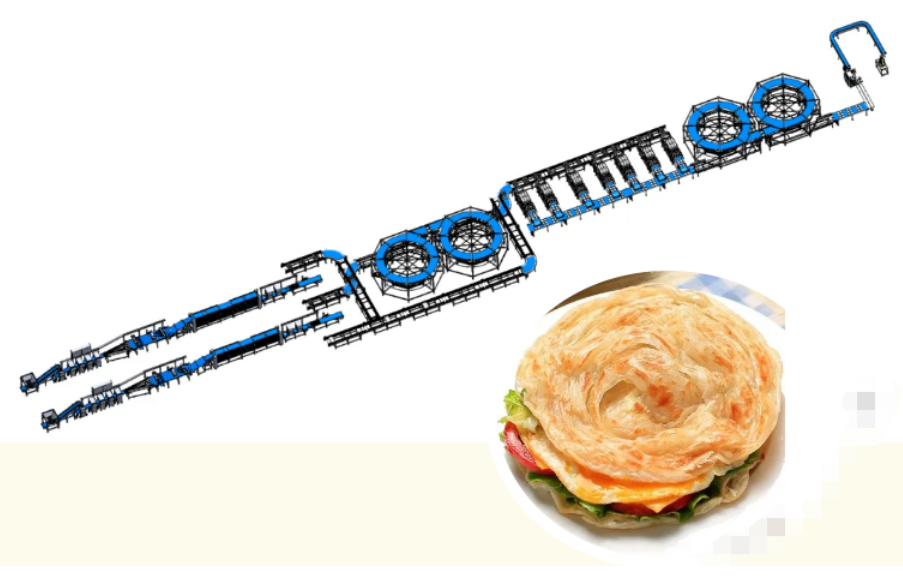

Automatic Lacha Paratha Production Line: A Blend of Classic and Innovation

Chenpin's classic masterpiece—Automatic lacha Paratha production line, draws its inspiration from ChinaTaiwan's hand-pulled pancakes. As a pioneer in the industry, Chenpin's independently developed production line has successfully entered the international market, with global sales exceeding 500 sets. The unique feature of this production line lies in its multifunctionality; it is not only capable of efficiently producing hand-pulled pancakes but also flexibly adapts to the production of scallion pancakes, various types of pies, and Tongguan pancakes. Its excellent adaptability significantly enriches the customer's production line and enhances their competitiveness in the market.

Automatic Pizza Production Line: Ultra-high Capacity, Customization Unlimited

The unique one-stop pizza production line has won market recognition with its outstanding production efficiency and customized services. This production line is not only capable of efficiently producing traditional pizzas but also flexibly meets the production of innovative boat-shaped pizzas, satisfying a variety of market demands. Leading companies in the industry, Chenpin has a profound understanding of the exquisite craftsmanship in pizza making, skillfully blending automation technology with the art of handcrafting to ensure that every pizza presents the perfect flavor and appearance. Consumers of any nationality can find a choice that satisfies their taste buds from the pizzas produced by Chenpin.

ChenPin Food Machine Co., Ltd, with professionalism, innovation, and service at its core, is committed to providing the world's food enterprises with the highest quality one-stop overall plant planning solutions. Chenpin has always strived to grow from a small product to a big brand, with the core focus on "professional R&D and manufacturing of various types of automated dough production lines," continuously breaking through its own limitations and leading the industry trend.

Post time: Aug-19-2024

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)